COMPANY INTRODUCTION

GUANGZHOU NFC TRANSFORMER CO.,LTD is a Taiwan-based company. Focus on the develop and manufacture many kind of transformer. Main products have Toroidal transformer, EI lamination transformer, C core transformer, high frequency transformer and big power transformer. Now the factory covers an area of about 6000m2 and 150+ employees,daily output is 3000-5000pcs. Products are customized design, but there is no MOQ requirements.

- 1993 Founded in Taichung, Taiwan. Mainlyproduced toroidal transformer.

- 2002 China factory established, located inGuangzhou, China.

- 2004 Developed and produced El Lamination transformer.

- 2006 Earned ISO 9001 Certihcation.

- 2007 Big power transformer division set up and start to produce big power transformer.

- 2010 Developed and start to produced C core transformer and high frequency transformer

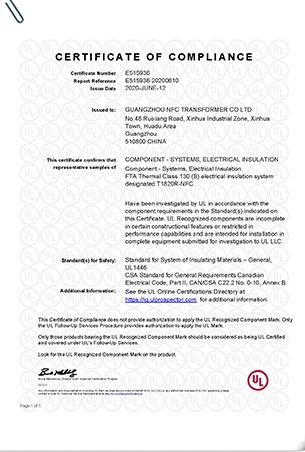

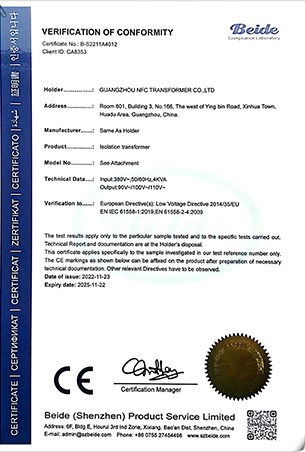

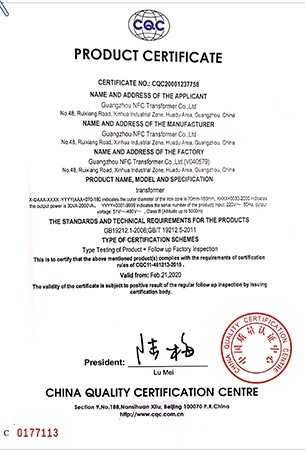

- 2020 Earned UL,CQC and CE certification.

- Production Line

- Test Equipment

CLIENT

CLIENT

-

Accurate design

With professional R & D skills, provide accurate design solutions for various application fields.

-

Exquisite workmanship

Each production process is based on standardization and technical skills. Pursue innovation first and Keep improving.

-

Honest service

24-hour service a day. Adhere to customer first. Be anxious when customers feel anxious,think about what customers will think about. Customer satisfaction as the service - oriented, to create a better cooperation prospects.

|

01 |

CoreAfter passing the appearance inspection, we will do 100% test about core loss and exciting current , to ensure that the value of core loss and exciting current are under the range of customer require. |

|

02 |

Copper wirewill measure the size of diameter, do the salt water pinhole test, Breakdown voltage test, Electrical resistance and Mandrel winding test for the coat of copper wire. |

|

01 |

SOP(standard operation procedure (SOP) is set up in each process. |

|

02 |

The first 10PCS article run should be confirmed prior to the production run. The final confirm have to approve by the supervisor of design department and quality assurance department and signature. |

|

03 |

In the process of batch production, IPQC monitor momently. If there is any issue about quality, organize the quality management group immediately to analyse the root, and make improvement soonest. |

|

04 |

All the electric performance is with 100% test. eg: Exciting Current, Insulation for layer and layer copper wire, Loading test, Hi-pot and etc. |

|

05 |

The testing equipment is complete. eg: Touch Current Tester, Power Analyzer, AC & DC Withstand Voltage Tester (Hi-pot Tester), DCR Analyzer, Dual Display Digital Multimeter, Impulse / Surge Tester, 3KW AC Power Source, 10KW AC Power Source and etc. And all equipment will send out to regular aligning gear for correction periodically. |

|

06 |

After the product completing, quality assurance department will sampling for electric performance and appearance. The test is including temperature test for small quantity. |

|

07 |

Each batch of our products has a traceable label. Traceable label can showed as yy ww, bar code and QR code. The order instruction number can be found by traceable label. Through order number, material requisition and productive process record, we can find which batch materials were used and production quality status and who made it. All record can be traceable. |

|

08 |

And packing department will do 100% checking on appearance when packing (Appearance inspection include: finished size, outlet position, length of flexible lead wire, housing and etc). |

Get Your Best Solution Today!

We take care of every procedure from design & development to prduction & testing.