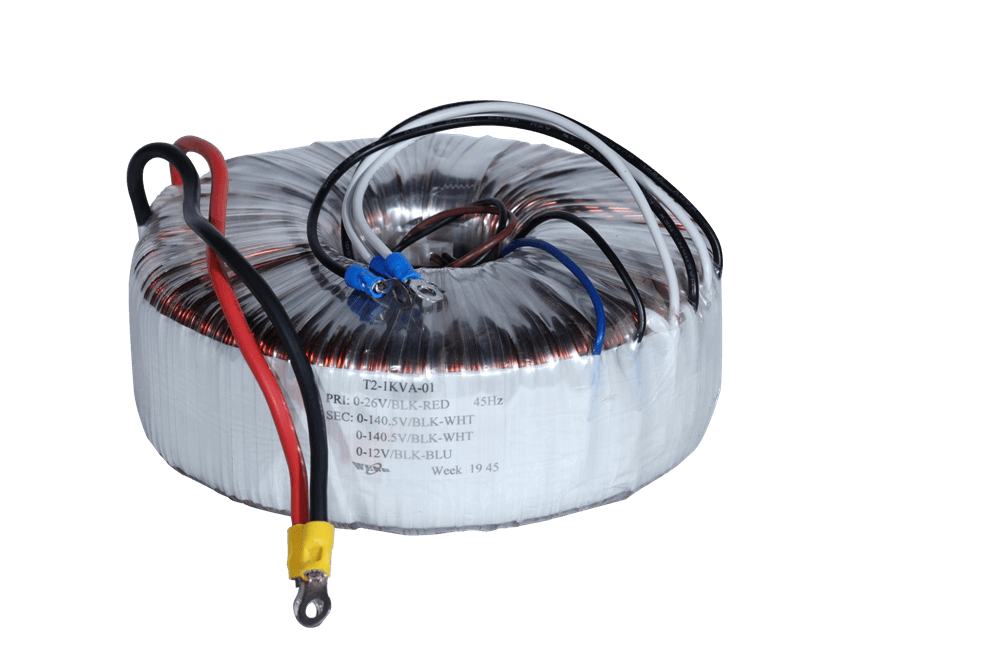

POWER: 1000W

SIZE: 162 (OD) x 52 (ID) x 72(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

The inverter equipment requests the transformer must has sufficient power, indirect load and low temperature rise. In transformer’s design , it needs to moderately increase the reluctance in the magnetic circuit, to reduce transformer instantaneous start current.

Power Range: 50VA to 3000VA

Phase: Single or 3 Phase

Input/Output: Customized

Insulation: up to 4kV (Hi-pot)

Sample Lead Time: 3~5 days

Production Lead Time:3 Weeks (Urgent order can be negotiated)

Quantity:No MOQ Require

Specification Table

| Power | Regulation |

Temperature Rise |

Efficiency | Size(mm) | Power | Regulation |

Temperature Rise |

Efficiency | Size(mm) | |||

| (VA) | (%) | (℃) | (%) | OD | H | (VA) | (%) | (℃) | (%) | OD | H | |

| 50VA | 12.5% | 45℃ | 88% | 89 | 36 | 900VA | 4.6% | 65℃ | 95% | 152 | 75 | |

| 75VA | 12.5% | 55℃ | 88% | 89 | 42 | 950VA | 4.5% | 65℃ | 95% | 162 | 71 | |

| 100VA | 11.0% | 55℃ | 89% | 100 | 38 | 1000VA | 4.5% | 65℃ | 95% | 162 | 72 | |

| 150VA | 9.0% | 55℃ | 90.5% | 106 | 43 | 1100VA | 4.4% | 70℃ | 95.0% | 162 | 75 | |

| 200VA | 8.0% | 55℃ | 92.0% | 114 | 50 | 1200VA | 4.3% | 70℃ | 95.2% | 163 | 78 | |

| 250VA | 7.6% | 55℃ | 92.5% | 116 | 50 | 1300VA | 4.2% | 70℃ | 95.3% | 172 | 76 | |

| 300VA | 7.0% | 55℃ | 93.0% | 122 | 56 | 1400VA | 4.1% | 70℃ | 95.4% | 172 | 79 | |

| 350VA | 6.5% | 60℃ | 93.3% | 123 | 57 | 1500VA | 4.0% | 70℃ | 95.5% | 172 | 84 | |

| 400VA | 5.8% | 60℃ | 93.5% | 131 | 57 | 1600VA | 4.0% | 75℃ | 95.5% | 180 | 88 | |

| 450VA | 5.6% | 60℃ | 93.7% | 121 | 58 | 1700VA | 4.0% | 75℃ | 95.5% | 180 | 90 | |

| 500VA | 5.5% | 60℃ | 94.0% | 132 | 63 | 1800VA | 3.9% | 75℃ | 95.5% | 180 | 93 | |

| 550VA | 5.4% | 60℃ | 94.0% | 132 | 68 | 1900VA | 3.9% | 75℃ | 95.5% | 181 | 94 | |

| 600VA | 5.2% | 65℃ | 94.2% | 142 | 64 | 2000VA | 3.8% | 75℃ | 95.5% | 181 | 100 | |

| 650VA | 5.0% | 65℃ | 94.3% | 142 | 69 | 2300VA | 3.5% | 75℃ | 96.0% | 195 | 93 | |

| 700VA | 4.8% | 65℃ | 94.5% | 142 | 72 | 2500VA | 3.5% | 75℃ | 96.2% | 196 | 94 | |

| 750VA | 4.7% | 65℃ | 94.5% | 142 | 75 | 2600VA | 3.4% | 75℃ | 96.3% | 196 | 99 | |

| 800VA | 4.7% | 65℃ | 94.5% | 152 | 70 | 2900VA | 3.3% | 75℃ | 96.4% | 206 | 105 | |

| 850VA | 4.6% | 65℃ | 94.6% | 152 | 72 | 3000VA | 3.2% | 75℃ | 96.4% | 206 | 106 | |

NFC Transformer provides both standard and custom designs with following features.

Toroidal Transformer Main Materials (IQC process)

All the material is inspected strictly with ISO9001:2015 quality program.

Core: appearance inspection and core loss test.

Copper wire: pinhole test and coat of adhesion test

Toroidal Transformer Process

Transformer Testing Items

Two mounting way for choice.

1. Rubber + Metal disk Assembly

2. Epoxy in the centre